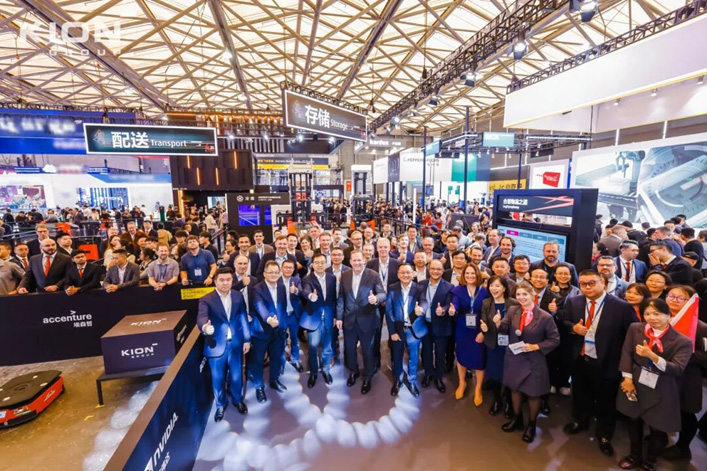

On the opening day, the Linde booth was bustling with people and exuded a lively atmosphere. At the highly anticipated opening ceremony, Rob Smith, CEO of KION Group, was invited to take the stage. Guided by the host, he took the baton. As he waved his arm, a melodious symphony filled the air, and Linde’s handling robots sprang into action. Performing automated collaborative operations in harmony with the beautiful melody, they precisely completed tasks such as storage, retrieval, handling, and stacking. This performance broke the traditional, cold, and mechanical impression of industrial equipment, presenting the audience with a precise and aesthetically pleasing industrial art performance.

Rob Smith, CEO of KION Group, delivered a speech, stating, “This exhibition is an important strategic showcase for KION Group in the Asian market. China is not only a crucial market for KION Group but also a vital engine for its global innovation. We have combined German heritage with Chinese intelligent manufacturing to establish a solid localized business system in China, continuously enhancing KION’s overall competitiveness on a global scale.”

Indoor Exhibition Area | Immersive Experience: The Perfect Fusion of Virtual and Reality in the “Future Warehouse”

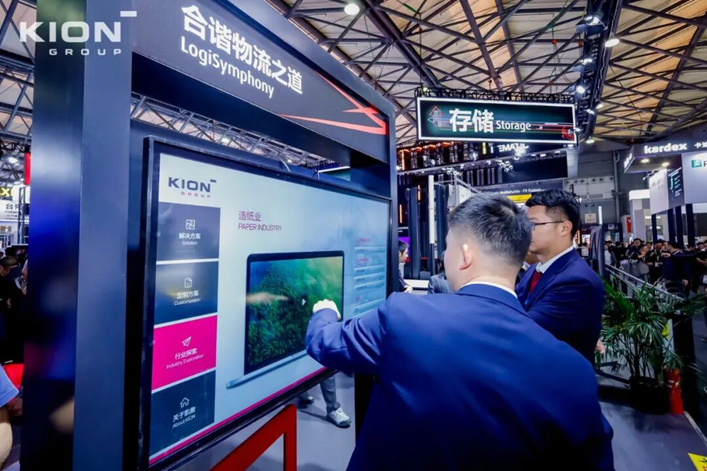

Upon entering the indoor exhibition hall, visitors are first greeted by KION’s multimedia interactive digital screen. This touchscreen integrates all products and industry solutions from the KION Group. Visitors can select work scenarios according to prompts, and the system will intelligently match and generate customized logistics solutions. This intuitive and convenient digital interaction method has attracted a large number of visitors to stop and experience it.

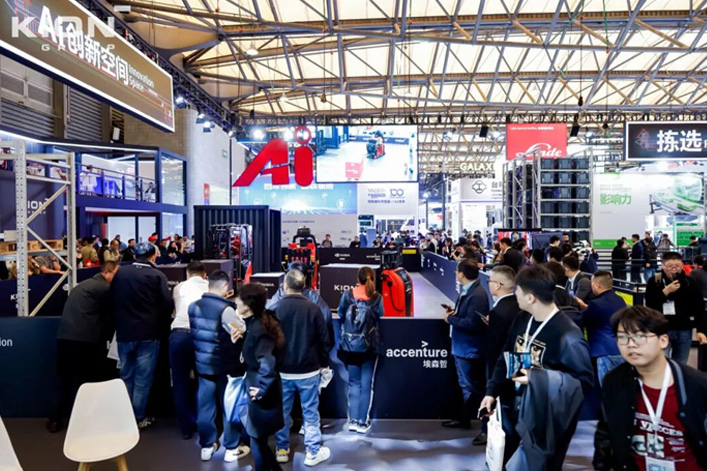

In the AI Innovation Space area, KION Group showcased its future warehouse model, developed in collaboration with NVIDIA and Accenture, for the first time in Asia. Inside the exhibition area, four forklifts in operation simulated a human-machine hybrid warehousing scenario, reproducing the entire process from inbound storage to outbound delivery. By using AI cameras to capture real-time data on-site and intelligently identify cargo types and plan routes, the entire area operates efficiently and smoothly. Meanwhile, through digital twin technology, the real-time dynamics of the exhibition area are reconstructed 1:1 in a virtual world and displayed synchronously on a large screen at the site. KION Group fully leverages artificial intelligence technology to comprehensively reshape the reasoning, perception, and decision-making capabilities of logistics systems, designing the ideal layout for future warehouses for customers in different industries.

On the other side of the AI Innovation Space, it was equally bustling. Linde has created a miniature automated logistics smart factory here, accurately simulating real production line and warehouse environments. Powered by Linde’s MyMA full-stack application software as the intelligent management hub, with a three-tier software system architecture, it connects the three functional exhibition areas of storage, distribution, and picking, comprehensively showcasing Linde’s “software-hardware integrated” one-stop flexible automated logistics solutions. Visitors can observe automated operation modes in different scenarios up close and experience the technological charm of smart logistics.

Several newly launched automated “star solutions” were also on display and attracted significant attention. These include a counterbalanced robot with an innovative dual-pallet design, specifically designed for high-frequency turnover scenarios of heavy goods; 4 – ways shuttle of pallet system tailored to high-density storage needs, greatly improving space utilization; a pallet handling robot with a compact body design, combining flexibility and high-speed operation characteristics; and a bin picking robot solution with fast picking capabilities and smooth operation. These innovative products have become the focus of the exhibition due to their outstanding performance, attracting numerous merchants to stop and exchange ideas.

Chingpong Quek, CTO & President KION Group ITS APAC, said, “As a global leading supplier of supply chain solutions, KION Group has always been at the forefront of the industry, deeply integrating artificial intelligence and digital twin technology into every link of the logistics supply chain and actively promoting this technology to the Chinese and global markets. In the future, we will continue to collaborate with ecosystem partners to jointly explore more advanced and intelligent logistics solutions and co-create a brand-new future for smart logistics.”

Outdoor Exhibition Area | Hardcore Technology + Industry Customization: Experience Material Handling in the Innovative Era

01

The outdoor exhibition area was equally bustling. At the entrance, Linde showcased its full range of product matrices, transitioning from oil to electric and covering warehouse vehicles to electric handling vehicles, ranging from 1.5 tons to 32 tons. This provides customers with green and efficient handling options for different work scenarios.

02

In the Application Industry Solution area, Linde systematically presented logistics solutions for various scenarios, from inbound and outbound operations to distribution and storage. Industry experts were also present to communicate one-on-one with guests.

03 At this exhibition, Linde specially set up a technology exhibition area to demonstrate the in-depth integration concept of “German heritage & Chinese intelligent manufacturing.” Through a combination of physical displays and video presentations, Linde visually showcased its innovative breakthroughs in core technology areas such as batteries, motors, and electric controls, as well as its diverse range of new energy solutions. Many industry professionals and technicians engaged in in-depth discussions, expressing high recognition for Linde’s solid R&D capabilities and rigorous manufacturing processes.

04

In the vast outdoor exhibition area, the most eye-catching feature was a tree symbolizing the “KION Full Value Chain.” It vividly illustrated the “full-scenario coverage, full-lifecycle management, and full-ecosystem collaboration” full value chain service system constructed by KION Group. Through a comprehensive combination of high-quality products and services, it empowers customers to maximize the value of warehousing and logistics.

05

At the site, in addition to showcasing its hard power, KION Group also demonstrated its soft power. Its nationwide service network and diverse and flexible cooperation models successfully drove numerous merchants, including e-commerce giants, industry major clients, and dealers, to sign contracts on-site.

This CeMAT ASIA exhibition will continue until October 31. During the exhibition, KION will also hold multiple themed forums, collaborating with industry experts and ecosystem partners to conduct in-depth discussions on cutting-edge topics such as “the path to upgrading enterprise logistics systems,” grasp frontier trends, and jointly explore more possibilities for “harmonious logistics.”

]]>題-2-1.jpg)

On Jan 20, 2025, Linde and G-power successfully completed a bulk delivery ceremony for hydrogen fuel cells trucks in Puyang, Henan.?Chingpong Quek, Member of the Executive Board, CTO of KION Group, and President of KION ITS APAC, along with over a hundred guests including government leaders from Puyang municipalities, counties, and districts, industry experts, and industry chain partners, attended the ceremony to witness the delivery.

At the ceremony, Chingpong Quek, Member of the Executive Board, CTO of KION Group, and President of KION ITS APAC stated, “As an industry pioneer, Linde forklifts continue to leverage our technological advantages and global enterprise platform to accelerate the strategic layout of hydrogen energy, a cutting-edge new energy technology, and provide customers with more suitable, advantageous, and reliable product solutions. In 2020, Linde began its layout in the Chinese market for hydrogen forklifts,strengthening cooperation with China’s local hydrogen energy ecosystem and developing multiple fuel cell prototypes, which have provided important support for the development of the Chinese hydrogen fuel cell forklift market.”

Currently, Linde and G-power have jointly developed 3-5-ton hydrogen forklift products that can be adapted to different application scenarios.

The delivery of 30 forklifts will be fully utilized by customers in the chemical, food, and energy industries in Puyang, expanding the application scenarios of hydrogen energy in Henan Province. This represents a revolutionary breakthrough in the application of fuel cell technology in industrial vehicles and also showcases to the world a Chinese solution for fuel cell industrial vehicles, marking a milestone.

]]>

On Jan 9, a handover ceremony for over 50 new Linde shared forklifts, including various models, was successfully held at Nonggu Smart Cold Chain Logistics Park in Jinzhong, Shanxi. Linde provided a zero-threshold, efficient, and economical leasing program. The forklifts can be rented via mobile apps, optimizing resource allocation and enhancing operational efficiency, thus aiding the park in becoming a modern, green, and intelligent logistics base.

首席執(zhí)行官Rob-Smith-1.jpg)

On Jan 7th, in Las Vegas, USA, KION GROUP announced a partnership with Accenture to optimize supply chains leveraging NVIDIA’s advanced artificial intelligence and simulation technologies. At the Consumer Electronics Show (CES) held in Las Vegas, the three companies demonstrated how clients can define the ideal layout for new warehouses and leverage NVIDIA Omniverse Mega, a large-scale industrial digital twin blueprint, to continuously improve existing facilities. This includes a physics AI-driven digital twin (an AI model embodying the principles and characteristics of the physical world) aimed at enhancing the performance of smart warehouses equipped with autonomous forklifts, intelligent cameras, and the latest automation and robotics solutions.

In his opening speech, Ching Pong Quek, President of KION APAC, highlighted the competition’s history, covering over 230 cities and involving more than 10,000 participants since its inception in 2007. The competition aims to promote safety and efficiency in forklift operations and nurture skilled talents in the logistics industry.

The finals saw intense competition among 29 teams in events like rapid stacking, forklift gymnastics, and a team relay. Changchun FAW International Logistics Co. won the championship and will represent China in the global finals in Germany.

The 2024 Linde Cup, incorporating Olympic spirit and cutting-edge technology like Linde’s new energy forklifts, underscores Linde’s commitment to innovation and safety. The event also featured interactive demonstrations with automation and digital solutions, showcasing the future of intelligent logistics. The competition concluded with a vibrant awards ceremony, celebrating the spirit of excellence and innovation in the logistics sector.

]]>

The 5th “Linde Cup” Global Forklift Professional Skills Competition – China station opening ceremony Xiamen Station competition in Linde Xiamen factory was opened on March 9th. “Linde Cup” was founded in 2007, known as the forklift industry’s “Olympic Games”, with many players, wide range, large scale, high difficulty, and it’s extremely challenging and entertaining. The first competition set a Guinness World Record in Shanghai. The Linde Cup, held every four years, has entered 200 cities across the country since its inception and attracted more than 8,000 players from 4,000 companies.

This year we combined the Olympic elements, designed the “Forklift Gymnastics”, “Dunk Master”, “Olympic Five Ring Relay Race” and other projects. The players showed superb skills, and it is tense and interesting.

In recent years, Linde China has been committed to sustainable development and environmental protection. Linde products meet all the environmental requirements of the Chinese market, and the emissions of many models have reached the EU Stage 3 standards, far higher than the emission standards of similar models in the market. In May 2023, the solar energy project of Zhangzhou Factory was officially completed and put into use. At the end of 2023, the construction of the solar energy projects in the Xiamen Factory and the Jinan Factory also officially began, and it is expected that the solar energy projects will also be officially put into use in March to April 2024. In addition, the KION Group has officially joined the Science Based Targets initiative (SBTi) in 2023, which also marks the Group’s commitment to sustainable development.

]]>

]]>

]]>